Alright, this is a pretty common topic floating around on discord, and I’d like to share my thoughts on the whole generic/gates idler pulley discussion.

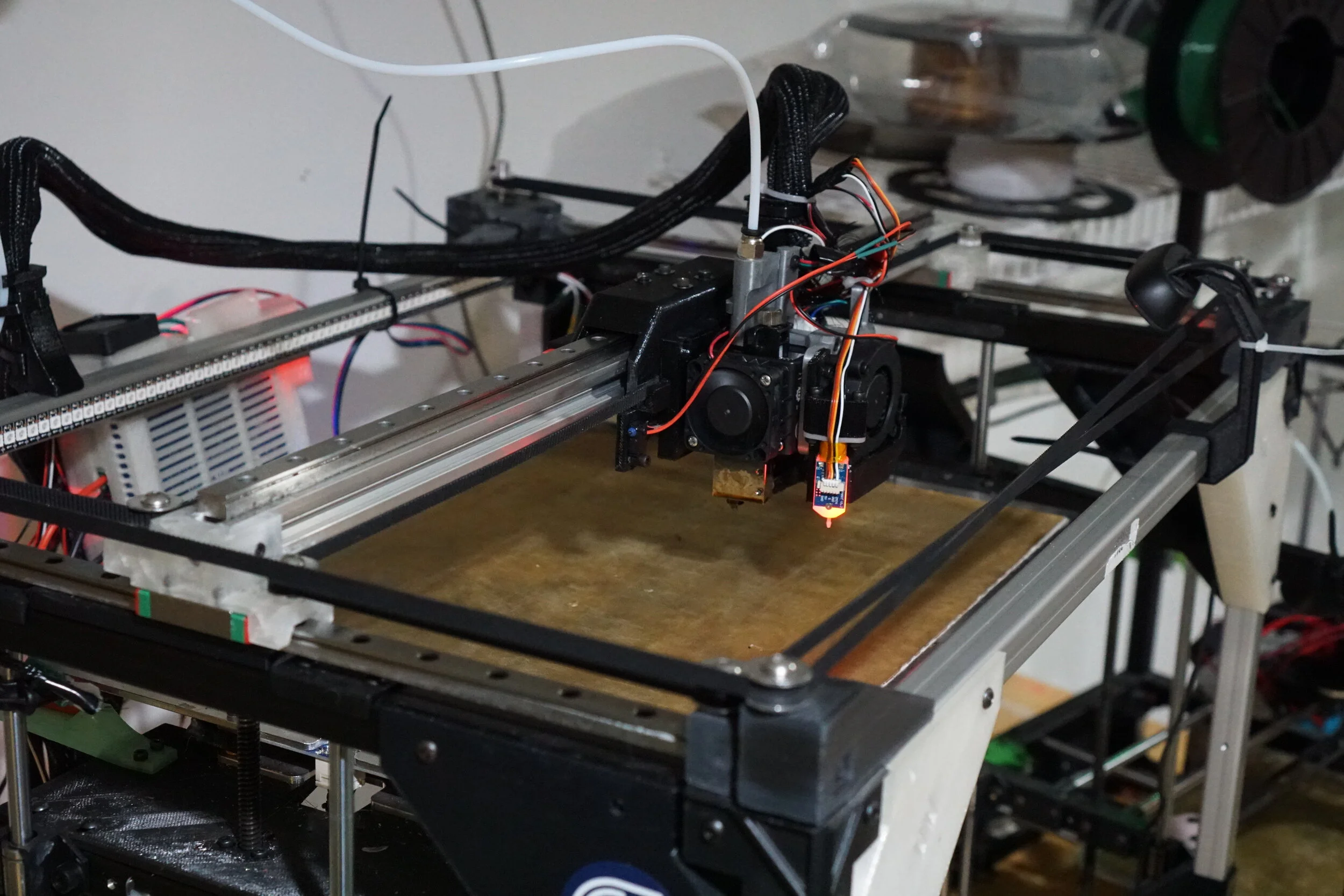

My first coreXY build was what I fondly call Mongo - a converted rigidbot that I brought to the darkside with a corexy gantry.

You can find more here: https://github.com/lukeslaboratory/CoreXY-Rigidbot-Conversion

This uses 6mm 20T equivalent idlers, which I purchased from a variety of sources and suppliers, some amazon, some aliexpress from different vendors. They all have come with 5mm ID ~8.5mm OD bearings on both the top and the bottom of the idler.

They work well for the machine size I have, which is ~26”x21” rectangular, and uses 6 of the toothed idlers as well as 2 of the smooth idler, using a generic GT2 belt.

I’ve been running for well over a year with this setup, and haven’t even been using any proper shoulder bolts, just using regular M5 screws threaded into the plastic corners. The motion system glides well and doesn’t have any hiccups or snags, and no obvious wear has happened over the 1000’s of hours that this has been in operation.

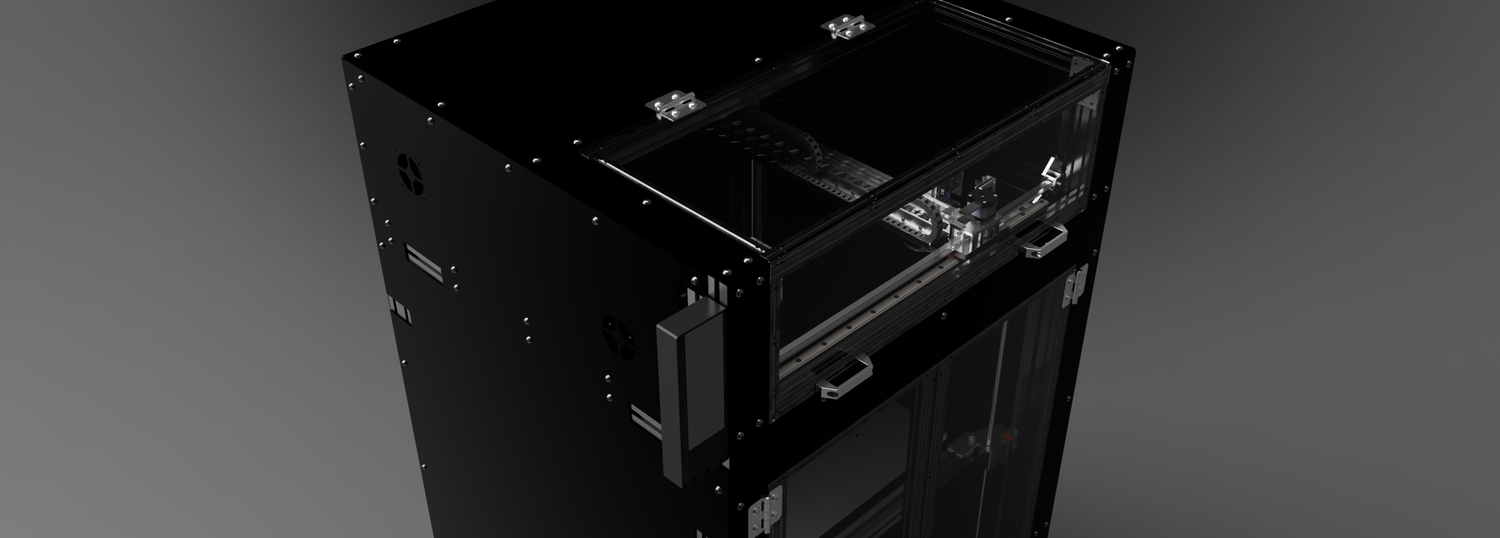

Now, with the stablebot, I admit that I slightly complicated the matter, and added another 2 toothed idlers and another 2 smooth idlers bringing the total to 8 and 4 each, respectively. I did some homework, and decided to use POWGE 9mm belts because of the positive review’s I’ve found elsewhere., and used proper shoulder bolts (also expensive!) to try to get a more constrained motion system to bring it up to the prosumer level I’m shooting for.

However, I set it up, and the gantry was significantly harder to move with my hand. Initially I attributed this to the different geometry, the 9mm vs 6mm belts, and the extra idlers and size. However, once I got the machine up to speed and started using it, it definitely seemed like something was a little off.

The biggest clue that something was wonky is while homing, the Y axis would home first, and then X homes, and while X is homing while Y is at 0, I could hear a faint clicking of the Ymin sensor being actuated. See the video below:

Here's a quick video showing what happens when you have generic 9mm idlers that stick in random places - Volume ON if you want to hear the idler

This caused me to wonder exactly what could cause this, and the only thing that made sense was if the idlers were sticking and the varying tension. Taking some of the idler posts apart and spinning by hand, it became readily apparent that there was some sticking at a minimum, and some of the bearings under tension/bearing load would get very “notchy” and stick and start. So the first thing I did was add in plastic top braces to place the shoulder bolts in double shear, to try to prevent the twisting that would really bring out the notchiness. This helped a little bit (plus is the correct design!) but as you can see above, this really wasn’t the solution, I still had the problem! Since the cost of more generics was nowhere near the cost of genuine gates, I gave another 10pack a shot. Nope. Maybe 3-4 were acceptable, but were still noticeably notchy.

Alright, this kind of performance isn’t acceptable, and its obvious that other implementations don’t have this issue. Lets go and see what’s the hubbub.

Gates on Top, Generic on bottom

Gates on the left - Smaller Flange OD, both on 5mm shoulder bolt

Comparing them on the same bolt, the difference was immediately apparent. HUGELY smoother. I could take my best generic bearing, and put it up against the gates, and you’d never want to ever use the generic again. the 6mm faired a bit better, but gates was still the clear winner. My guess is that the longer the idler, the tighter the bearing concentricity matters to keep the same smoothness.

I digress, I replaced everything on the stablebot with the gates idlers, and lo and behold, the machine feels like the piece of precision machinery it damn well should be. I can now move the gantry around easily by hand, even with significantly tighter belt tension, and it solved the issue with the notching, as you can see here -

I DO, however, still use generic pulleys attached to my motors, which continue to work well.

Long story short - are gates idlers necessary? For 6mm, At least with my generic supplies, No, not needed. Better, but not aggressively detrimental.

9mm and larger? Yep. Don’t mess around and get the right thing. I wish I had started out right.

Where you can get them:

E3d-Online direct - (affiliate links)

1 comment

sdgdsgsg