Alright - I admit that I haven’t been good at all with the promises I’ve made about blogging during stablebot creation. It’s been about 2 months since my last update, and I’m sorry that I haven’t spoken enough.

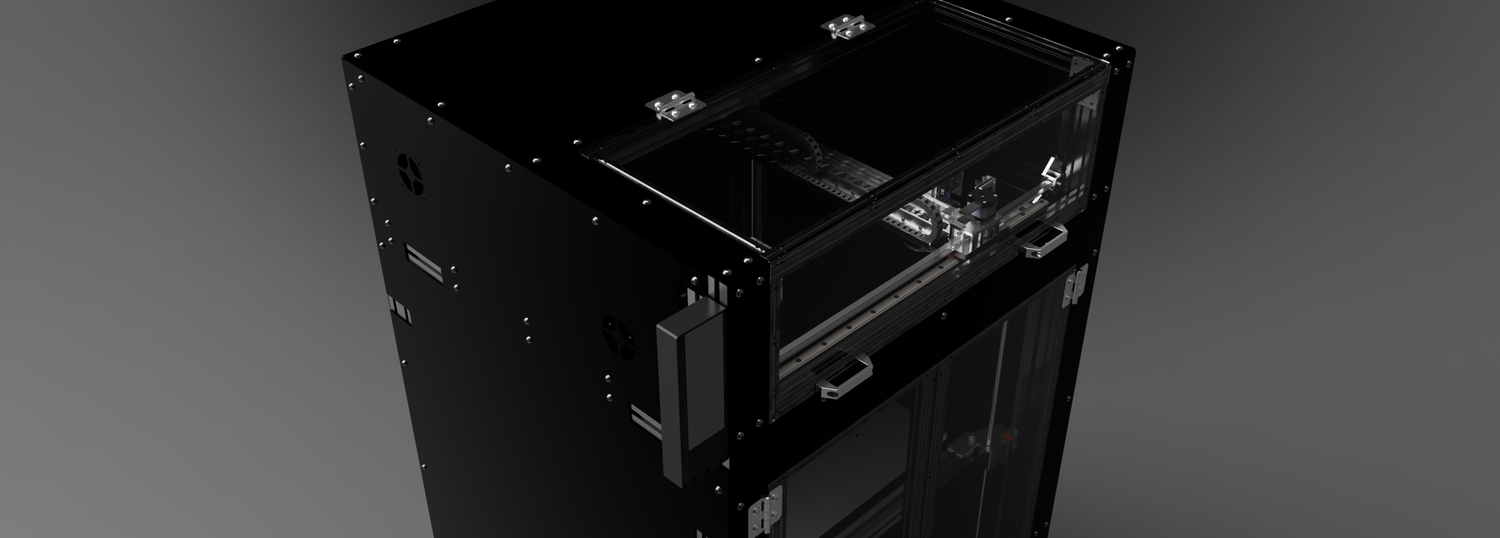

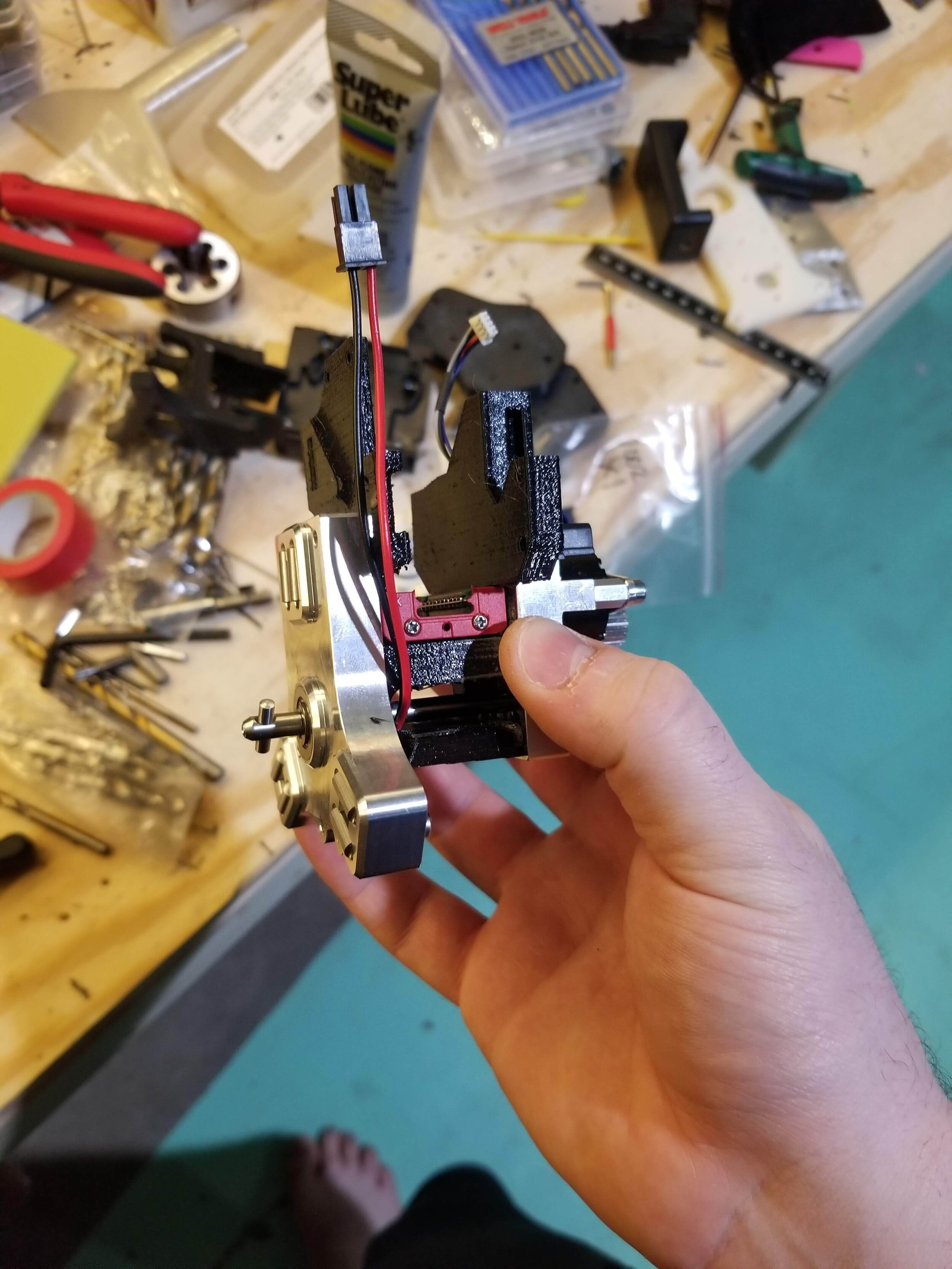

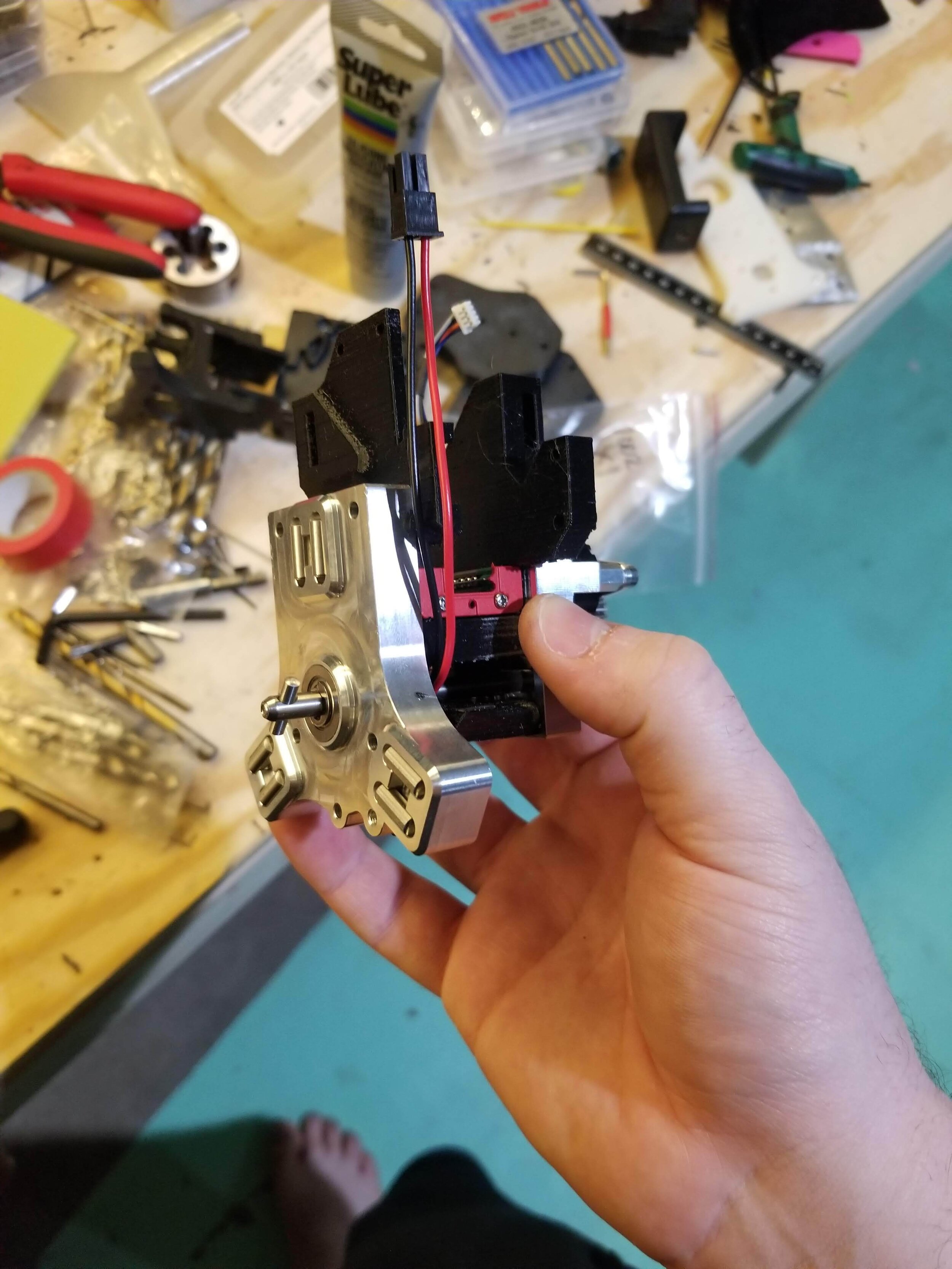

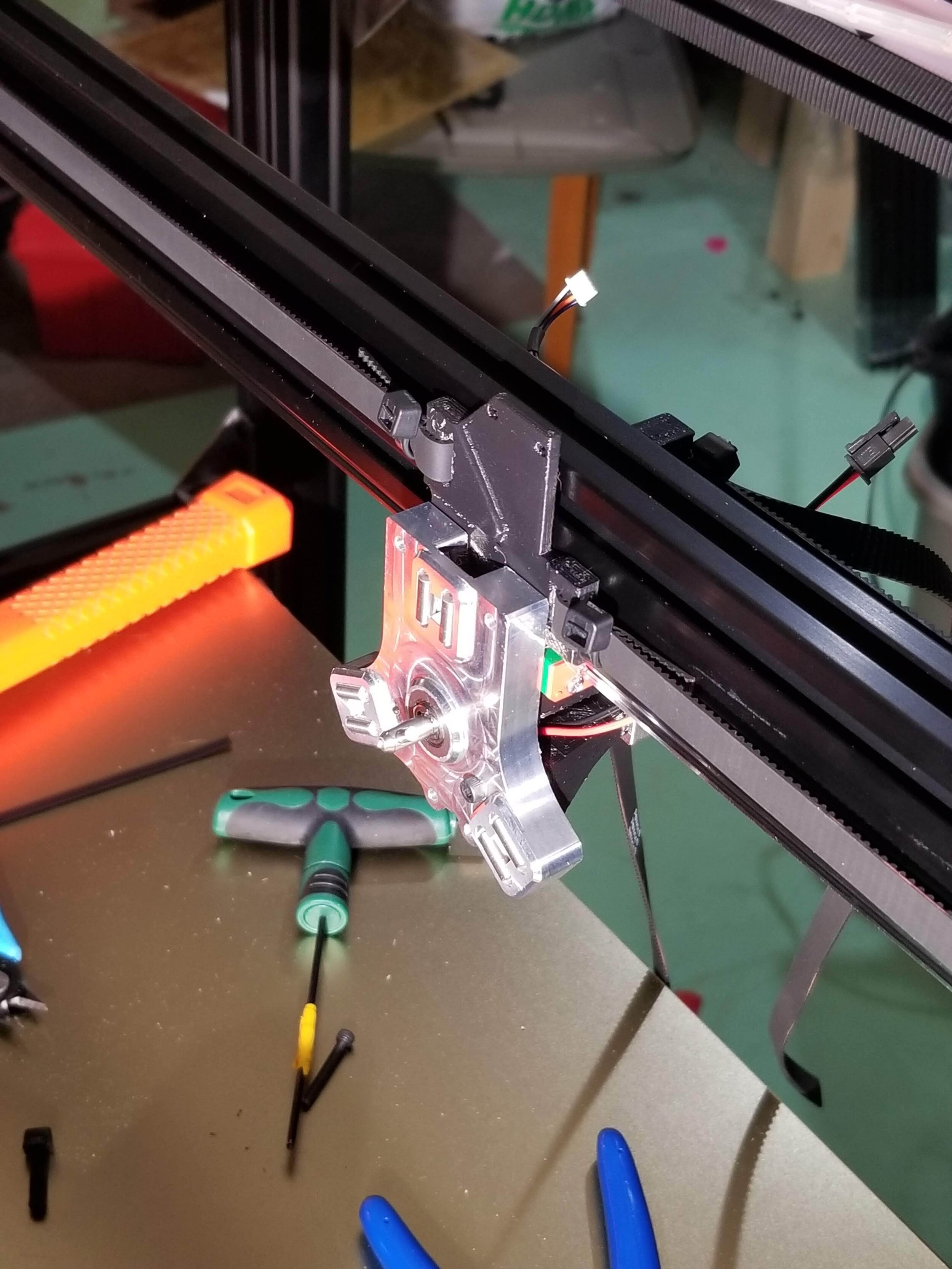

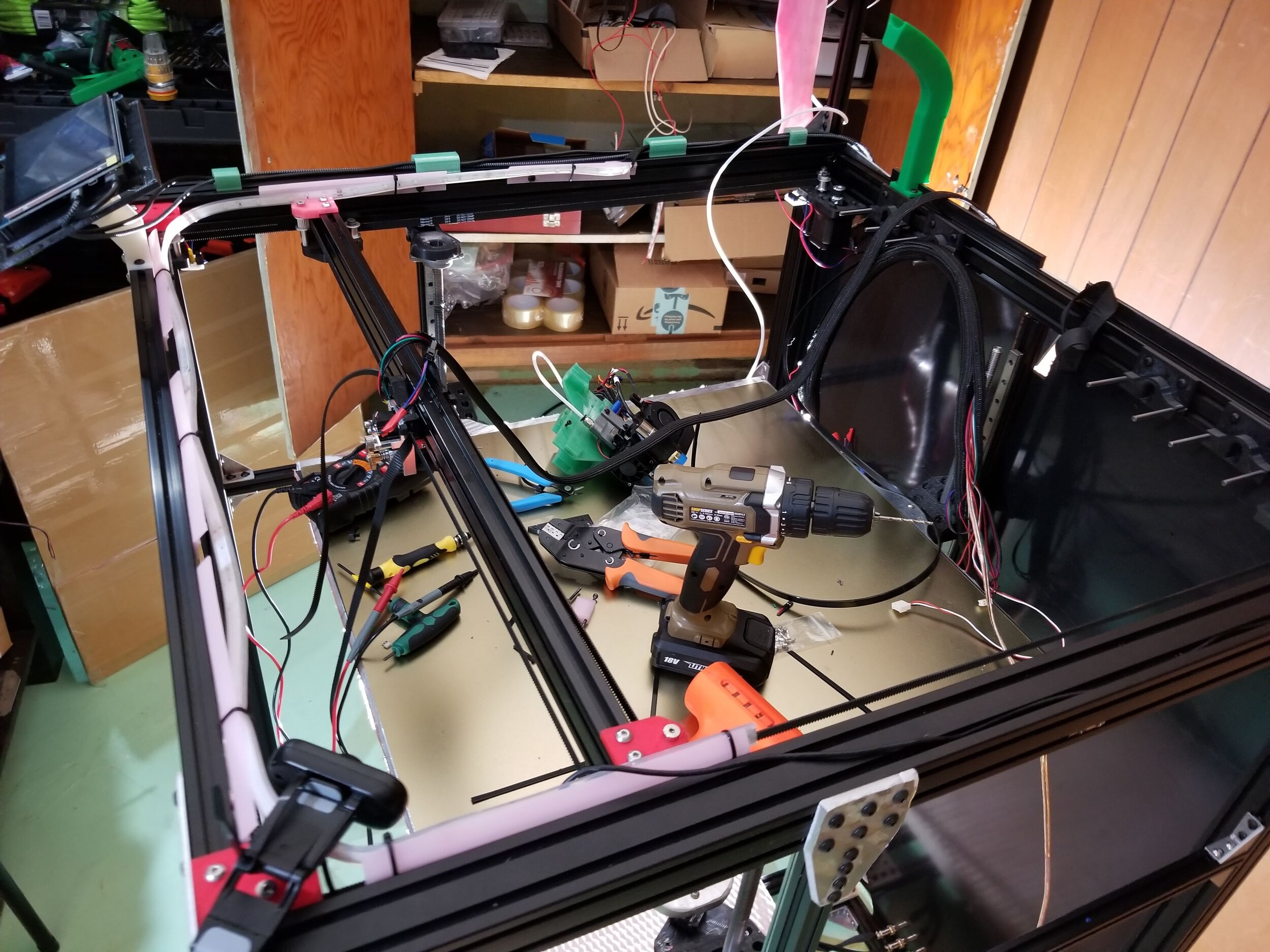

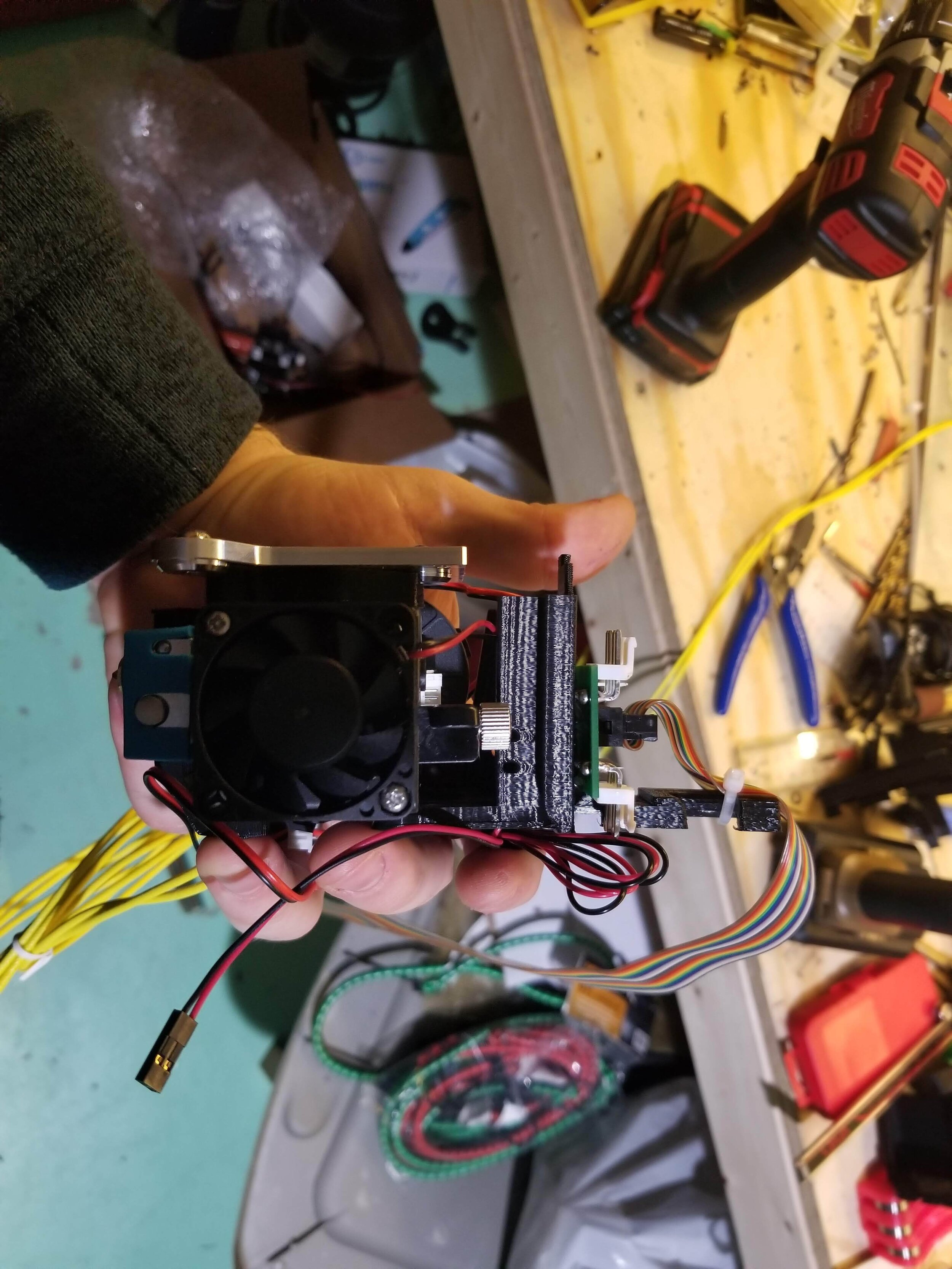

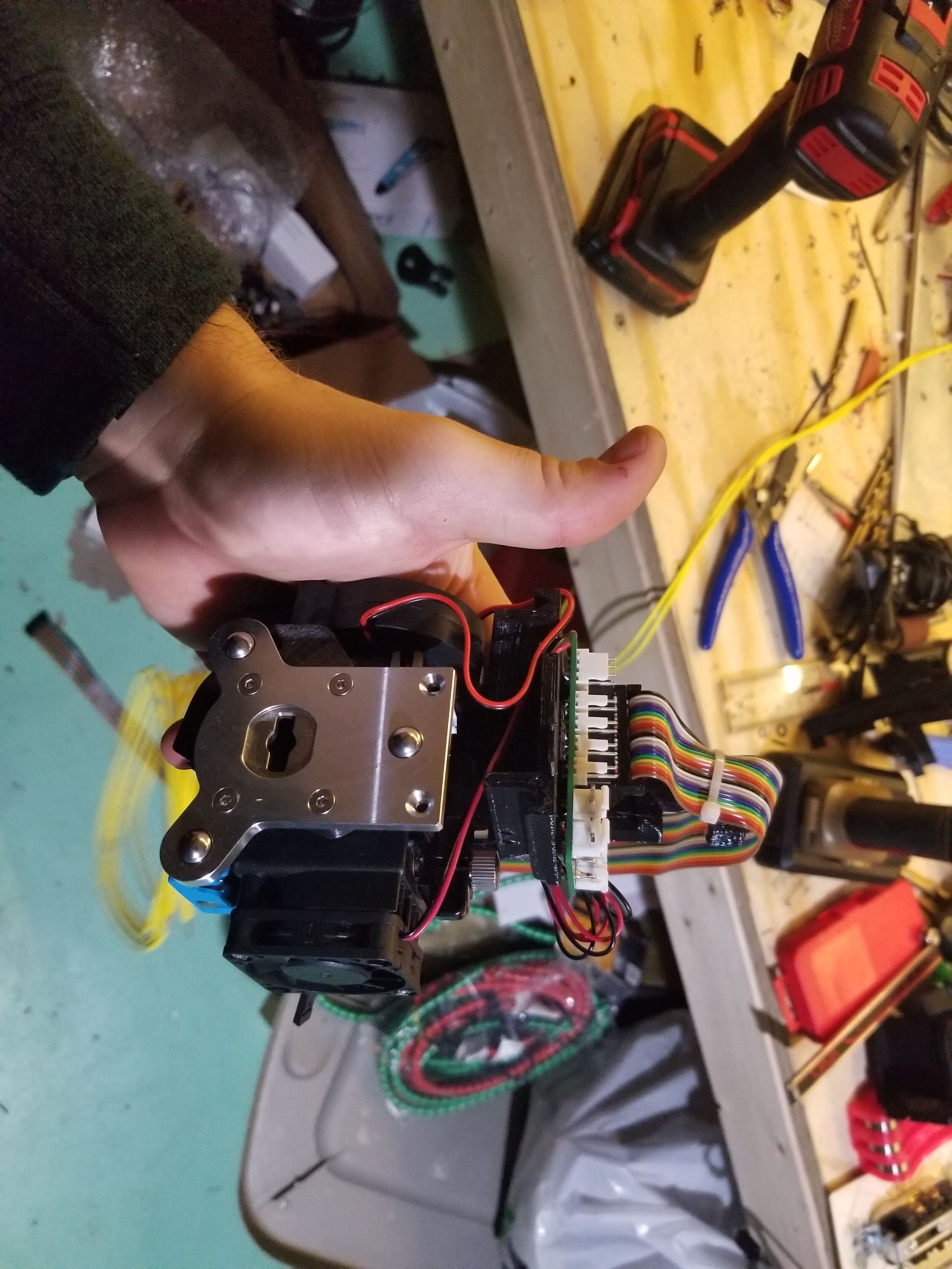

Things are progressing quite well in the lab. I’ve made some changes+upgrades that I didn’t expect to make, and partially due to coronavirus shipping issues, I’ve decided to swap to e3d’s toolchanger vs using the Jubilee cable driven one. I’m kinda a sucker for metal, so having the e3d-perfect machining is always a boon.

Here’s a list of all the progress from my last update, which you can see above in the gallery

-

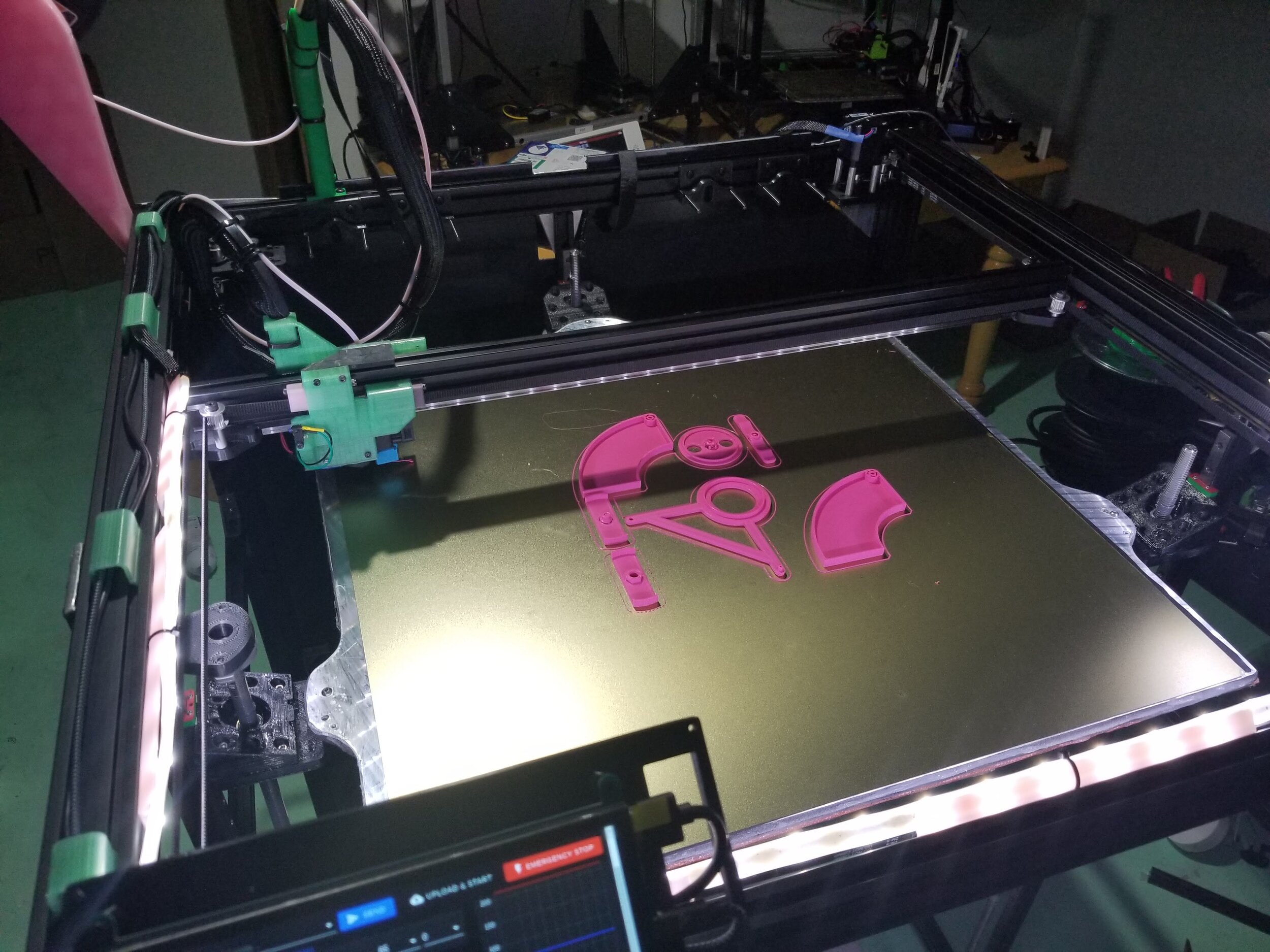

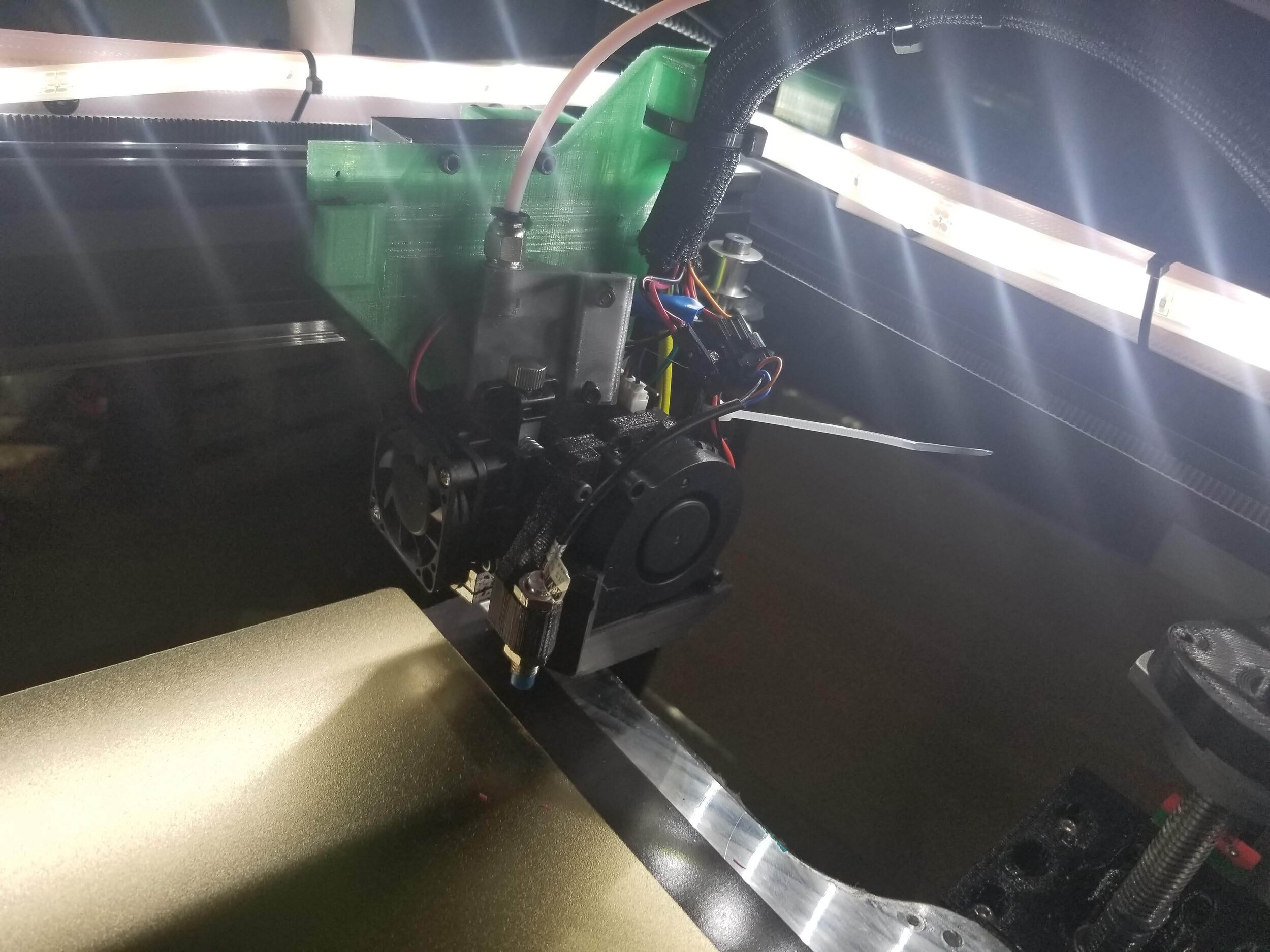

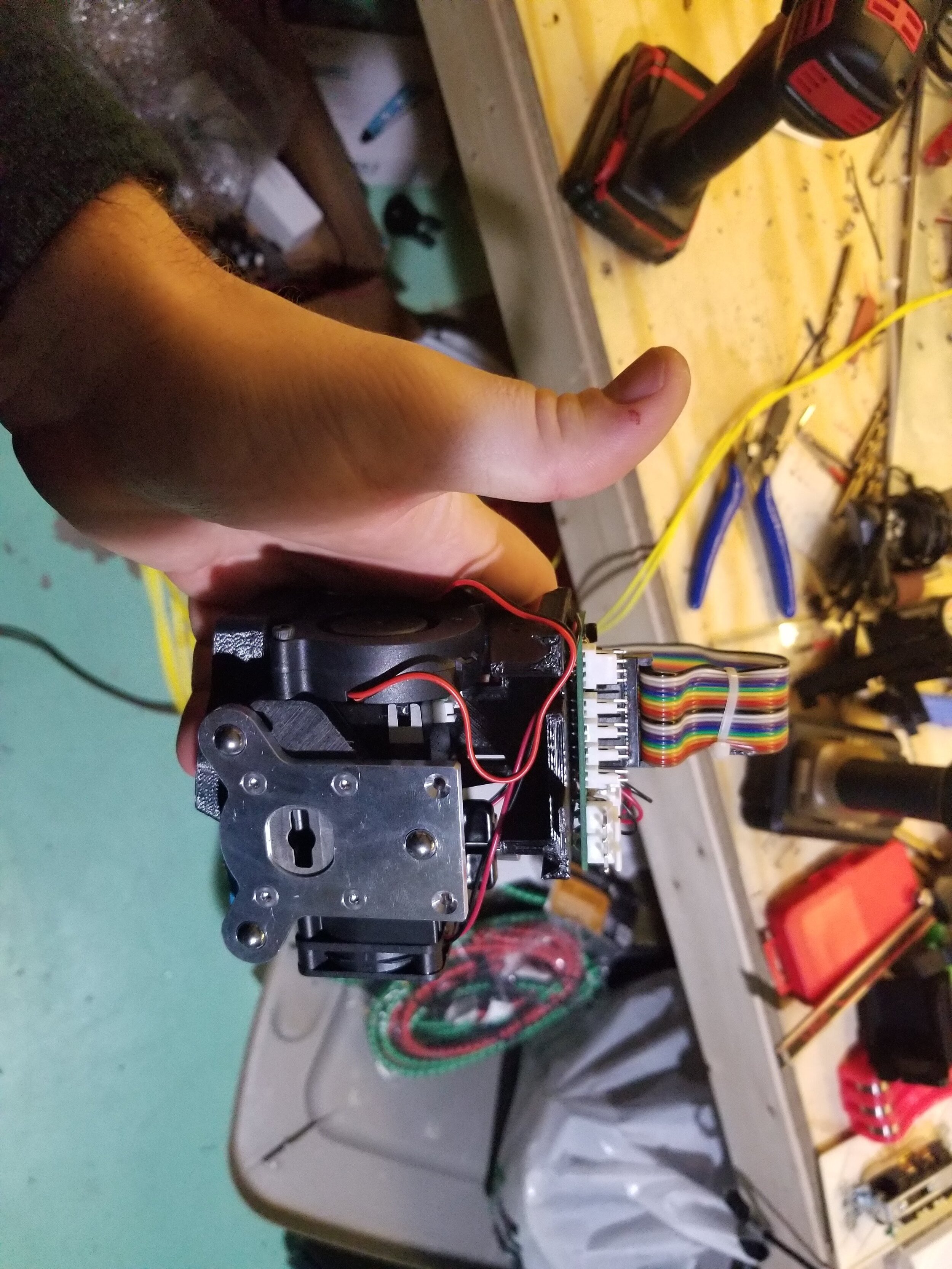

Removed direct hemera mount and adapted the machined e3d toolchanger to the gantry

-

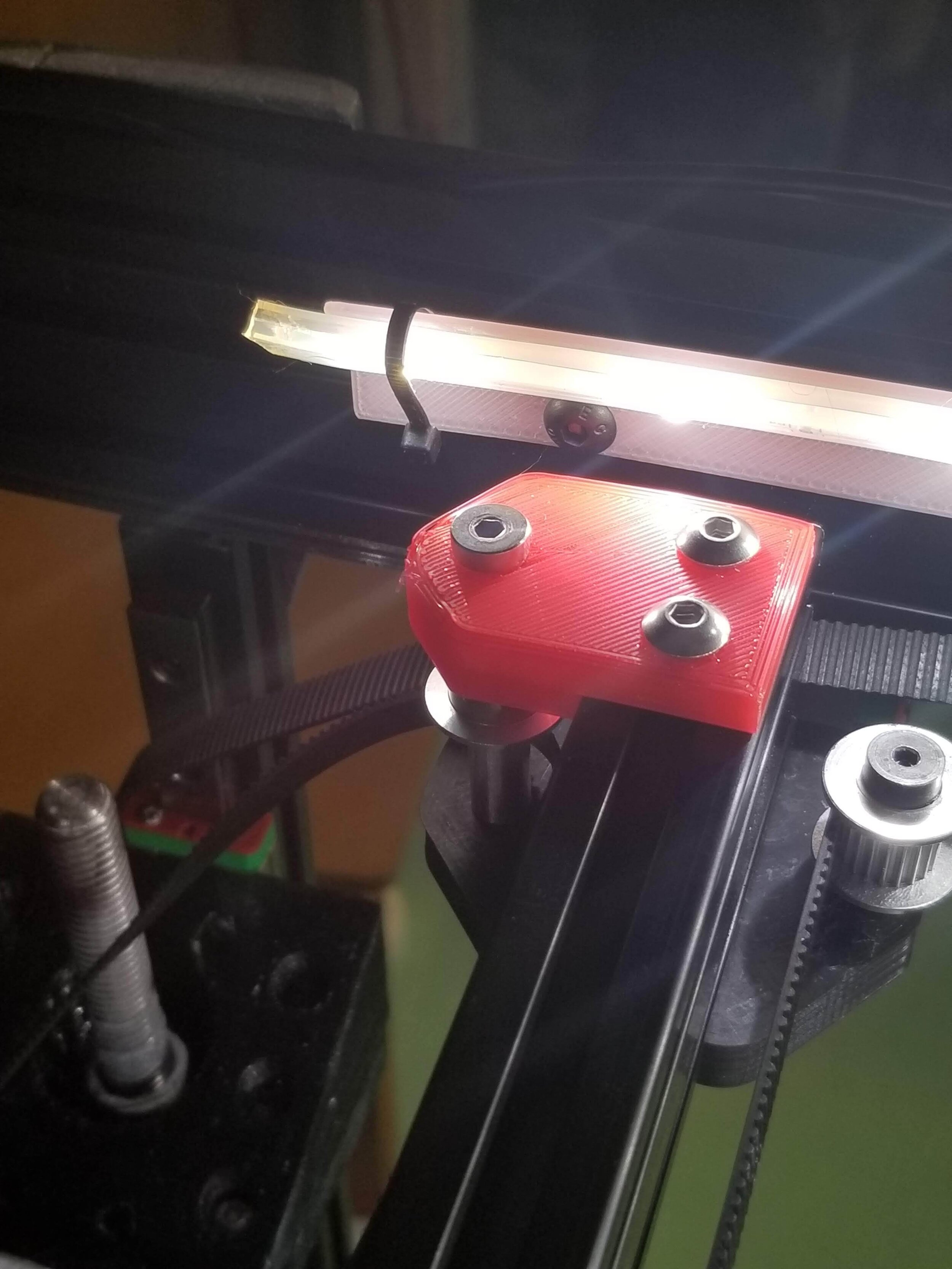

Swapped from generic 9mm pulleys to genuine Gates Pulleys - Will have its own post!

-

Before swapping to the gates pulleys - I added braces to put the pulleys in double shear - They seemed solid enough, but I was trying to diagnose an issue with very hard and jerky motion, so this was the “free” option.

-

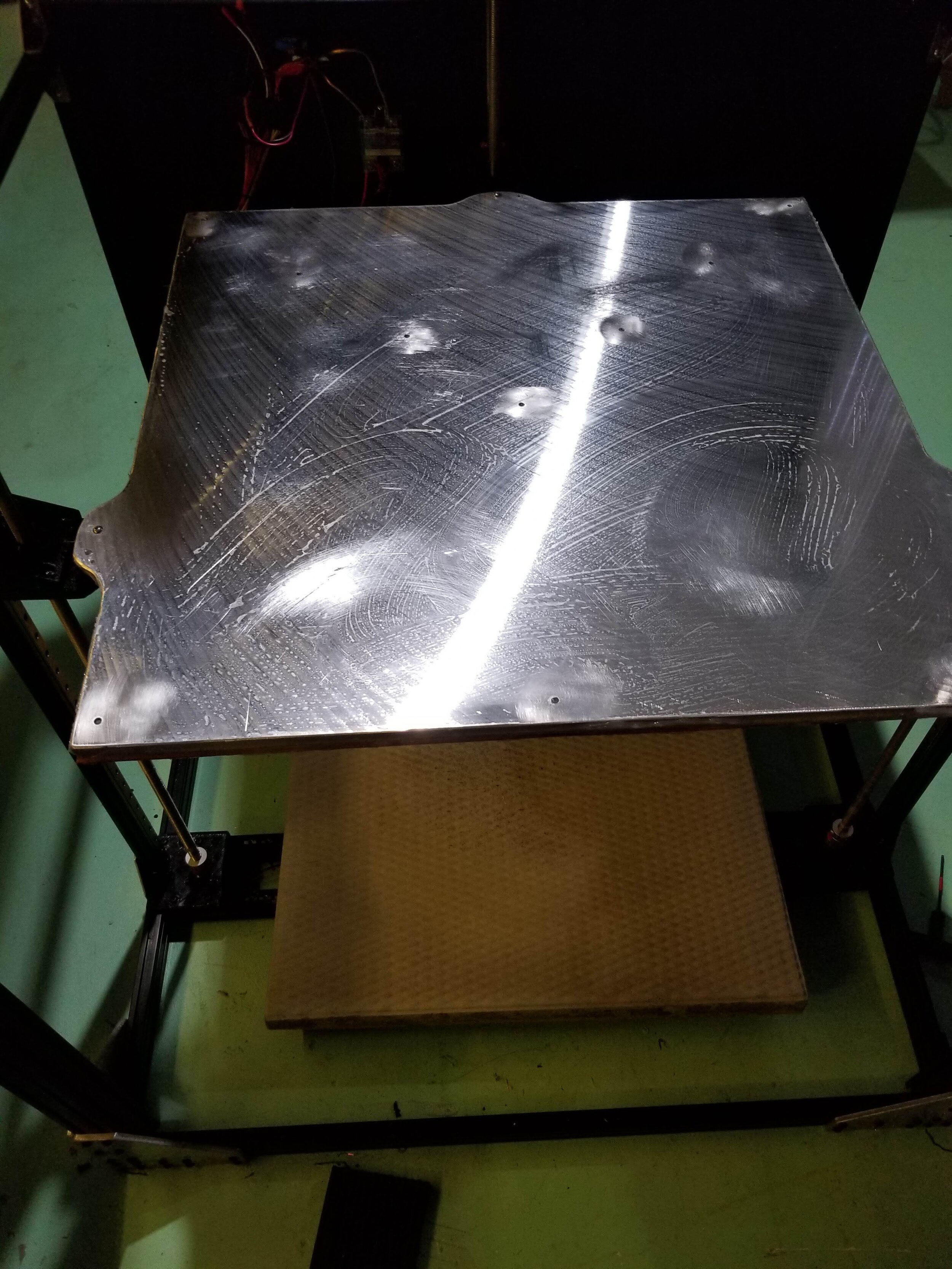

Finally recieved in a magnet-spring steel-PEI sheet bed - Works VERY well and PLA sticks wonderfully

-

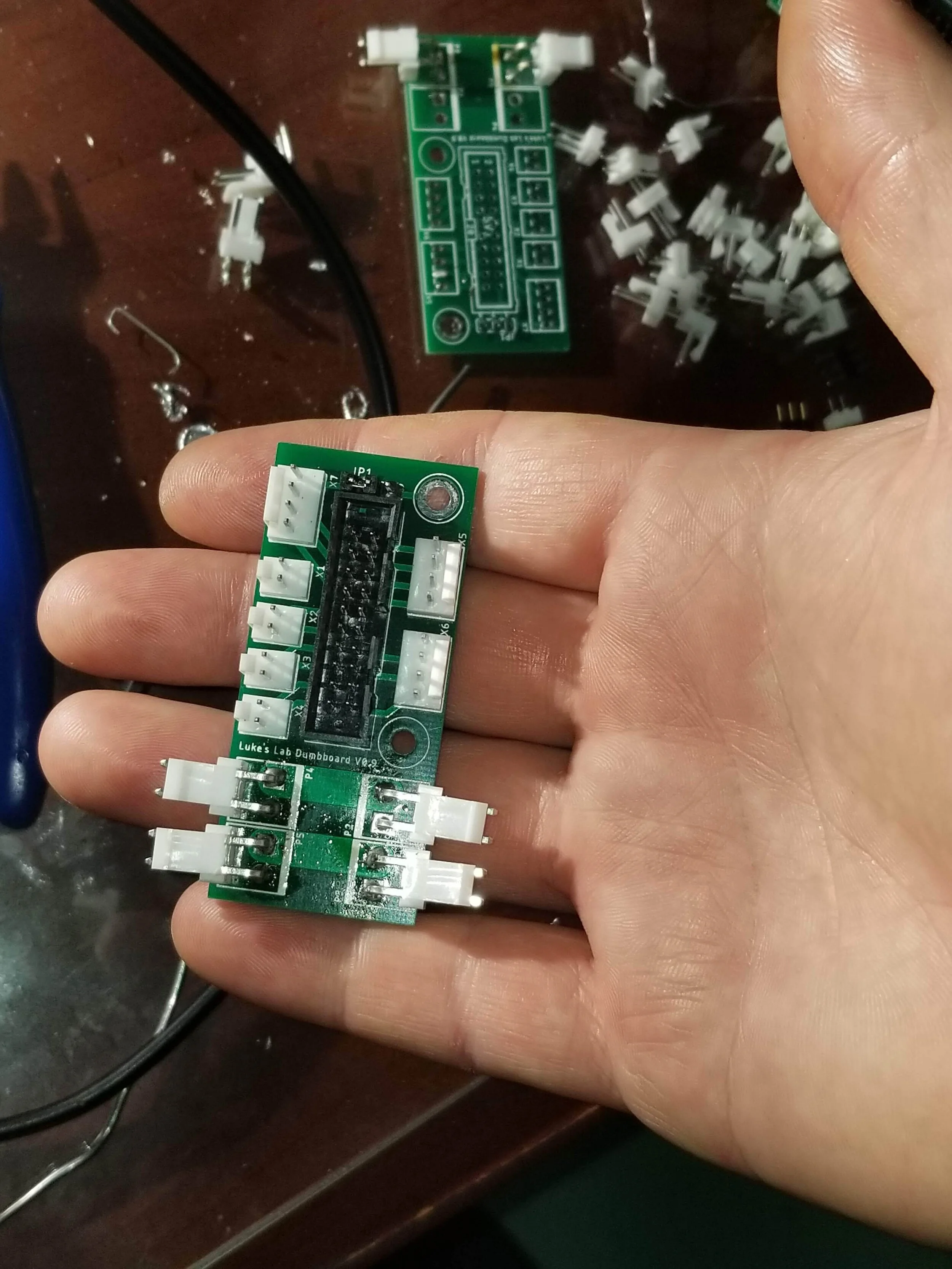

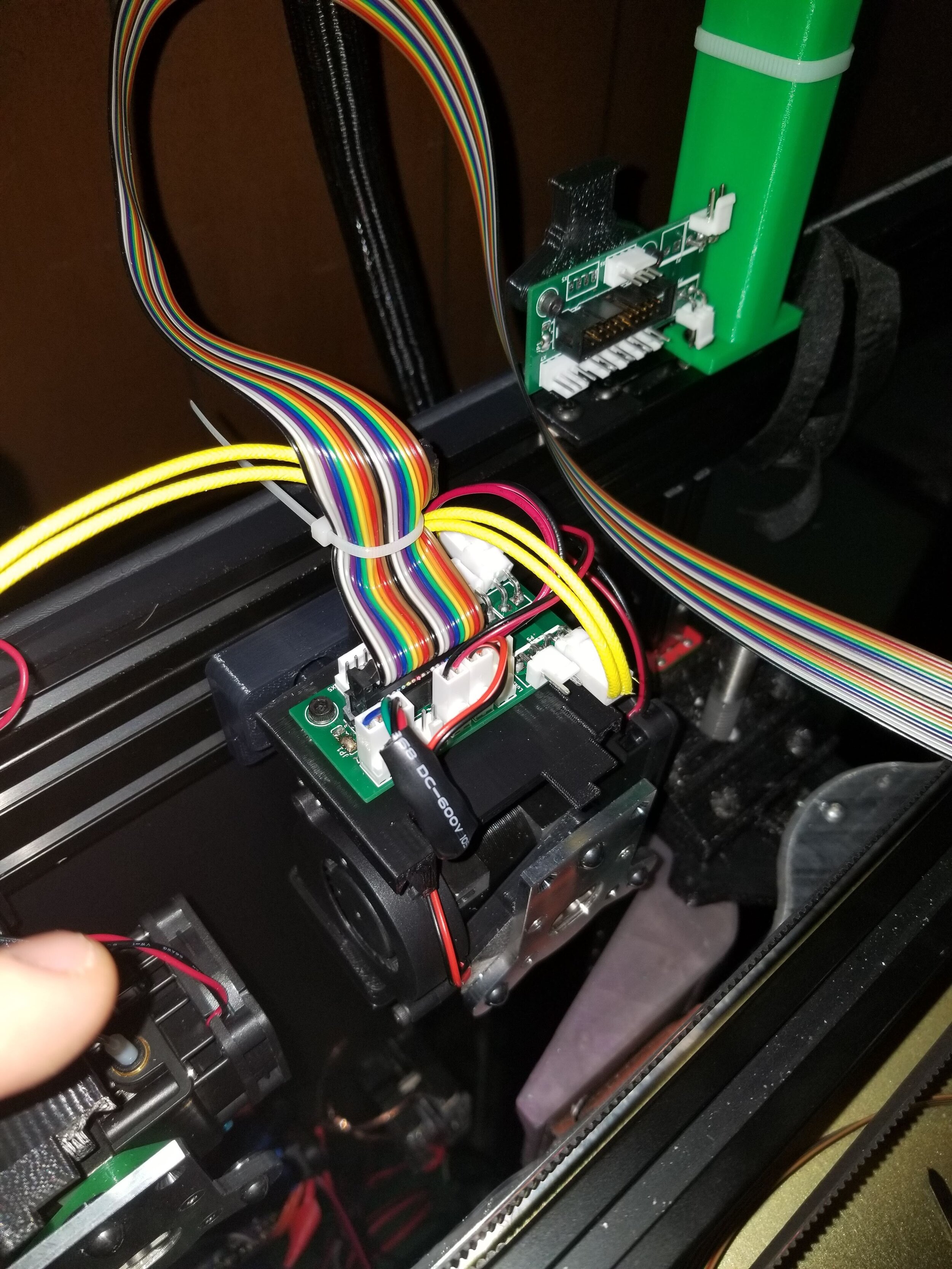

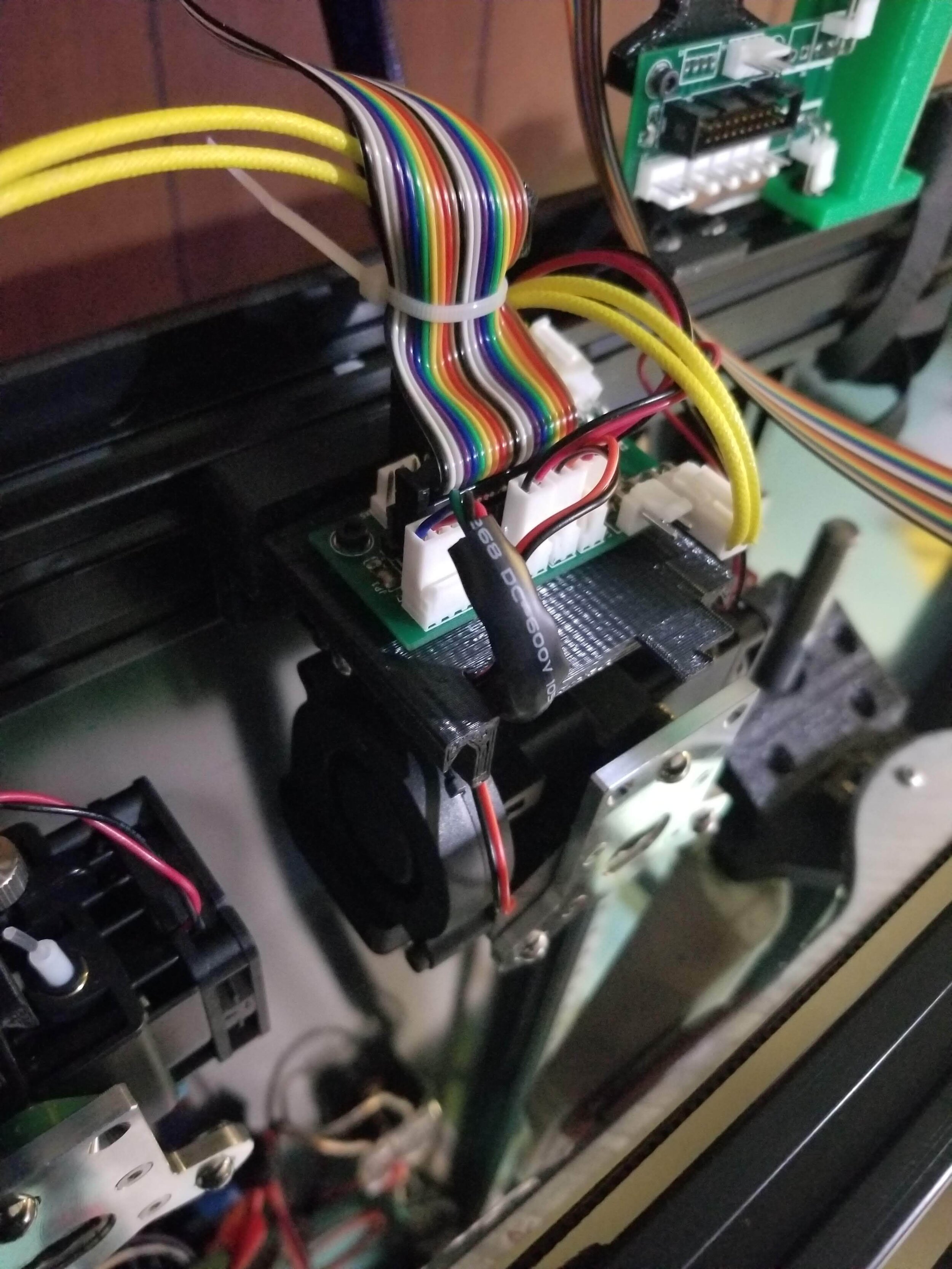

DUMBBOARD TOOL BOARDS ARE IN !! Very excited to have my first custom-designed boards come in - Greatly simplified my wiring and will make any swaps between tools very easy to execute.

-

I now have both my 3hc expansion board as well as the individual tool boards - I intend to run a mix of both, likely all 3 ports from the 3hc and then one ore two tools with the smart tool board.

-

AUTO BED COMPENSATION IS FIXED - this appears to be a bl-touch related issue, On the hemera-only mount i switched to an inductive sensor once I had the steel sheet, and with the e3d carriage with a simple switch, both work without adding a strange offset.